A vcb full form in electrical Vacuum Circuit Breaker (VCB) is a type of electrical circuit breaker that uses a vacuum as the arc-quenching medium. It is a popular choice for medium-voltage applications due to its reliability, low maintenance, and environmental benefits.

The vacuum has the highest insulating strength. So, it has far superior arc quenching properties than any other medium. The degree of vacuum is in the range of 10^-7 to 10^-5 torr. It is suitable for medium-voltage power distribution ranging from 22kV to 66 kV.

Working Principle: VCBs use a vacuum chamber to extinguish electrical arcs when the circuit is interrupted.

Vacuum Circuit Breaker (short notes)-

- It is mainly used for medium voltage ranging from 11 KV to 33 KV.

- high insulating medium for arc extinction as compared to the other circuit breaker. except air and SF6

- The pressure in a vacuum interrupter at the time of sealing off is kept at about 10-6 torr

- The moving contacts of the circuit breaker are move through a distance of 5 to 10 mm depending upon the operating voltage.

- After arc interruption, the recovery strength during the first few microseconds is 1 kV/µs second for an arc current of 100A.

- contact material of the high electrical conductivity so as to pass normal load currents without overheating.

- Because of the least requirements of maintenance, these breakers are very suitable for the system which requires voltage from 11 to 33 kV

Basic Working Principle Vacuum Circuit Breaker-

The basic working principle of a Vacuum Circuit Breaker (VCB) is as follows:

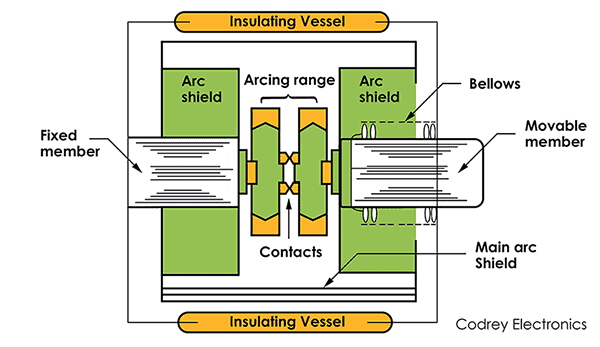

- Arc Formation: When the circuit breaker is opened, an arc forms between the fixed and moving contacts.

- Vacuum Chamber: The arc is drawn into the vacuum chamber, where the pressure is approximately 10^-4 Pa.

- Arc Extinction: The vacuum chamber extinguishes the arc by:

a. De-ionization: Removing ions and free electrons, making it difficult for the arc to sustain.

b. Heat Dissipation: Rapidly cooling the arc, reducing its temperature and energy.

c. Electrical Isolation: Preventing re-striking of the arc due to the high dielectric strength of the vacuum.

- Current Interruption: The arc is extinguished, and the current is interrupted.

- Contact Separation: The moving contact continues to move away from the fixed contact, maintaining electrical isolation.

VCBs use the unique properties of a vacuum to extinguish electrical arcs, making them a reliable and efficient choice for medium-voltage applications.

Vacuum Circuit Breaker MCQ-

Q: What is the arc-quenching medium in a VCB?

A) Air

B) Oil

C) SF6 gas

D) Vacuum

Answer: D) Vacuum

Q: Which of the following is an advantage of VCBs?

A) High maintenance

B) Low reliability

C) Environmental benefits

D) High noise

Answer: C) Environmental benefits

Q: What is the typical voltage range for VCBs?

A) Low voltage (less than 1 kV)

B) Medium voltage (1 kV to 36 kV)

C) High voltage (above 36 kV)

D) Extra high voltage (above 145 kV)

Answer: B) Medium voltage (1 kV to 36 kV)

Q: How often do VCBs require maintenance?

A) Every 1-2 years

B) Every 5-7 years

C) Every 10-15 years

D) Every 20-25 years

Answer: C) Every 10-15 years

Q: Can VCBs be used for high-voltage applications?

A) No

B) Yes, up to 36 kV

C) Yes, above 36 kV

D) Yes, above 145 kV

Answer: C) Yes, above 36 kV

Q: What is the lifespan of a VCB?

A) 10-15 years

B) 15-20 years

C) 20-30 years

D) 30-40 years

Answer: C) 20-30 years

Q: How do VCBs extinguish the arc?

A) By de-ionization and heat dissipation

B) By using a puffer mechanism

C) By injecting SF6 gas

D) By using a spring-loaded mechanism

Answer: A) By de-ionization and heat dissipation

Key Benefits:

- Fast arc extinction

- Low arc energy

- High dielectric strength

- Low maintenance

- Environmentally friendly

VCB full form in electrical Components:

- Fixed contact

- Moving contact

- Vacuum chamber

- Insulation

- Operating mechanism

Understanding the working principle of VCBs is essential for selecting, installing, and maintaining these critical electrical components.

Advantages:

- Low maintenance

- High reliability

- Low noise

- Environmentally friendly (no SF6 gas)

- Fast switching times

Applications:

- Medium-voltage power distribution

- Industrial control systems

- Renewable energy systems

- Electrical substations

VCBs are widely used in various industries, including power generation, transmission, and distribution, as well as in industrial and commercial applications.

Exam point mcq Vacuum Circuit Breaker (VCB)–

Q1: What is a Vacuum Circuit Breaker (VCB)?

A1: A VCB is a type of electrical circuit breaker that uses a vacuum as the arc-quenching medium.

Q2: How does a VCB work?

A2: A VCB works by drawing the arc into a vacuum chamber, where it is extinguished due to the lack of ions and free electrons.

Q3: What are the advantages of VCBs?

A3: VCBs offer low maintenance, high reliability, low noise, and environmental benefits (no SF6 gas).

Q4: What are the applications of VCBs?

A4: VCBs are used in medium-voltage power distribution, industrial control systems, renewable energy systems, and electrical substations.

Q5: How do VCBs differ from other types of circuit breakers?

A5: VCBs use a vacuum as the arc-quenching medium, whereas other breakers use air, oil, or SF6 gas.

Q6: What is the typical voltage range for VCBs?

A6: VCBs are commonly used for medium-voltage applications (1 kV to 36 kV).

Q7: Can VCBs be used for high-voltage applications?

A7: Yes, high-voltage VCBs are available for applications above 36 kV.

Q8: How often do VCBs need to be maintained?

A8: VCBs require low maintenance, typically every 10-15 years.

Q9: Can VCBs be operated manually or remotely?

A9: Yes, VCBs can be operated manually or remotely using electrical or electronic signals.

Q10: What is the lifespan of a VCB?

A10: The lifespan of a VCB can range from 20-30 years, depending on the application and operating conditions.

Types of Vacuum Circuit Breakers (VCBs)–

Vacuum Circuit Breakers (VCBs) come in various types, each designed to suit specific applications and environments. Below are the main types of VCBs categorized based on different factors:

1. Based on Voltage Levels–

- Low Voltage VCBs:

- Used in systems where the voltage level is relatively low, typically below 1,000 volts.

- Common in residential and small commercial applications.

- Medium Voltage VCBs:

- Designed for voltage levels ranging from 1,000 to 36,000 volts.

- Widely used in industrial and large commercial settings.

- High Voltage VCBs:

- Suitable for voltage levels above 36,000 volts.

- Often found in power generation plants and transmission substations.

2. Based on Installation Location–

- Indoor VCBs:

- Installed inside buildings or enclosed spaces.

- Typically used in industrial, commercial, and institutional facilities.

- Designed to operate in controlled environments, protected from weather elements.

- Outdoor VCBs:

- Installed in open or outdoor locations.

- Built to withstand harsh environmental conditions like rain, dust, and extreme temperatures.

- Commonly used in utility substations and power grids.

3. Based on Pole Configuration–

- Single-Pole VCBs:

- Designed to control one phase of an electrical circuit.

- Often used in systems where independent control of each phase is required.

- Three-Pole VCBs:

- Controls all three phases of a three-phase electrical circuit simultaneously.

- Commonly used in industrial and utility applications where balanced three-phase power is essential.

4. Based on Mechanism Type–

- Spring-Operated VCBs:

- Uses a spring mechanism to open and close the breaker contacts.

- Known for fast operation and reliability.

- Commonly used in both medium and high voltage applications.

- Magnetic Actuator VCBs:

- Uses a magnetic actuator to operate the breaker contacts.

- Provides precise control and is often used in applications requiring high-speed operation.

5. Based on Application–

- Industrial VCBs:

- Specifically designed for industrial environments, capable of handling high currents and voltages.

- Often used in manufacturing plants, refineries, and heavy industries.

- Commercial VCBs:

- Used in commercial buildings like malls, offices, and hospitals.

- Designed to protect electrical systems in environments where reliability and safety are critical.

- Utility VCBs:

- Used by utility companies in power generation, transmission, and distribution systems.

- Designed to handle high loads and ensure the stability of the power grid.

6. Based on Operation Mode–

- Manual VCBs:

- Operated manually by an operator who physically closes or opens the breaker.

- Suitable for applications where automation is not required.

- Automatic VCBs:

- Equipped with automatic control systems that detect faults and open the breaker without human intervention.

- Widely used in modern electrical systems for enhanced safety and reliability.

7. Based on Construction–

- Fixed Type VCBs:

- Installed in a fixed position within a switchgear assembly.

- Common in applications where the breaker is not frequently accessed or moved.

- Draw-Out Type VCBs:

- Mounted on a movable carriage, allowing the breaker to be easily withdrawn for maintenance or replacement.

- Provides flexibility in maintenance operations, commonly used in large industrial systems.

| Type of CB | Electromagnetic | Oil | SF-6 | Vacuum |

|---|---|---|---|---|

| Rated voltage, kV | 6-10 | 6-10 | 6-10 | 6-10 |

| Rated operational current, A | Up to 4000 | Up to 12000 | Up to 4000 | Up to 5000 |

| Rated breaking current, kA | Up tp 40 | Up to 90 | Up to 40 | Up to 63 |

| Electrodynamic withstand current, kA | 102 | 320 | 102 | 125 |

| Service life, years | 25 | 25 | 25 | 25 |