Earth testers, essential in electrical engineering, measure the resistance between electrical installations and the ground. This measurement ensures that electrical systems have proper earthing, providing a safe path for fault currents and preventing potential hazards. They help confirm that the earth resistance remains low, ensuring fault currents dissipate without endangering people or damaging equipment.

What is Earth Tester?

An Earth Tester is a specialized instrument used to measure the resistance between the electrical installation and the ground. Ensuring low earth resistance is critical in electrical systems to safely dissipate fault currents and minimize the risk of electric shocks, fires, and equipment damage.

Importance of Earth Resistance-

Electrical systems rely on effective grounding to protect against electrical faults, surges, and lightning. By maintaining a low resistance path between the equipment and the earth, fault currents are safely directed into the ground. This process prevents hazardous voltage buildup on metallic surfaces, ensuring human safety and the integrity of connected devices.

Digital Earth Resistance Tester-

Features

1- 3½ Digit (1999 Counts) 14mm LCD Display

2- Auto Power Off Function (after 3-5min.)

3- Low Battery Indication

4- Capable of Measuring Earth Voltage (0 – 10V AC)

5- Light Weight & Portable

6- Extremely Simple to Operate Connect – Press – Read

7- Designed to Reject High Levels of Noise & Interference

8-Designed to Generally Confirm to IS10656-1983

9- Range Selection & Single Person Push Button Operation Switches

10-Two Ranges for Earth Resistance Measurement

l1- Functions Icons on Display

l2- Battery Operated

l3- IEC 1010 CAT III 200V

l4- Sturdy, Elegant & Compact Body

Working Principle-

The Earth Tester injects current through an electrode in the ground and measures the potential difference across points using auxiliary electrodes. Typically, alternating current (AC) is used to minimize the effects of soil polarization and chemical reactions.

The resistance R is calculated using Ohm’s law: R=V/I

Here, V is the measured voltage across the electrodes, and I is the injected current. The accuracy of the reading depends on the proper placement of the auxiliary electrodes to prevent interference between different soil resistance areas.

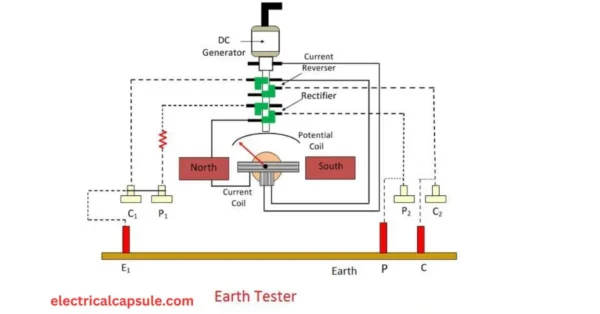

Components and Construction of an Earth Tester-

Earth testers typically feature:

- DC Generator: Often hand-cranked, producing power for testing circuits.

- Current Reverser and Rectifier: These regulate current and convert AC to DC, ensuring accurate readings unaffected by earth-induced back electromotive force (EMF).

- Commutators and Brushes: Transfer current between stationary and rotating components.

- Pressure and Current Coils: Placed in pairs, each pair is linked with auxiliary and earth electrodes. Their interaction helps in measuring earth resistance.

In operation, the tester’s rotating shaft drives the commutator, switching current directions smoothly. Proper positioning of auxiliary electrodes during testing ensures accurate resistance measurements by isolating interference between soil sections.

Methods of Earth Resistance Measurement-

- Fall-of-Potential Method:

- The most widely used technique.

- Two auxiliary electrodes are placed in a straight line with the earth electrode.

- Current flows through one auxiliary electrode while the voltage drop is measured with the other, providing the resistance value.

- Clamp-On Method:

- Measures resistance without disconnecting the earth system.

- A clamp-on tester induces voltage in the system and measures current leakage to calculate resistance.

- Useful for quick, non-invasive checks.

Multiple Choice Questions (MCQs) on Earth Tester-

1. What is the primary purpose of an Earth Tester?

A. Measure current leakage in electrical systems

B. Measure the resistance between the earth and the electrical installation

C. Detect short circuits in electrical networks

D. Measure voltage fluctuations in power systems

Answer: B. Measure the resistance between the earth and the electrical installation

Explanation: An Earth Tester ensures that electrical installations have a low resistance path to the ground. This is essential for safely dissipating fault currents to prevent electric shock and equipment damage.

2. What kind of current is typically used in Earth Testers?

A. Direct Current (DC)

B. Alternating Current (AC)

C. Pulsating DC

D. None of the above

Answer: B. Alternating Current (AC)

Explanation: Earth testers use AC to avoid polarization effects in the soil, which can cause measurement errors. AC also eliminates the electrolytic effect that DC could create over time.

3. In the Fall-of-Potential method, what is the role of the auxiliary electrodes?

A. They generate current for testing.

B. They act as ground references for measuring soil resistance.

C. They measure voltage drop between the earth electrode and potential points.

D. They protect the tester from overloads.

Answer: C. They measure voltage drop between the earth electrode and potential points.

Explanation: The auxiliary electrodes allow accurate measurement of the potential difference and ensure the earth electrode resistance is correctly assessed.

4. Which of the following is a key advantage of the Clamp-On Earth Tester?

A. It requires soil excavation.

B. It works without disconnecting the grounding system.

C. It only works on DC systems.

D. It measures voltage fluctuations.

Answer: B. It works without disconnecting the grounding system.

Explanation: The clamp-on earth tester is non-invasive and measures earth resistance without interrupting the connection, making it ideal for quick inspections in operational systems.

6. What type of maintenance should be performed for Earth Testers?

A. Battery replacement every month

B. Regular calibration to ensure accuracy

C. Lubricating the commutator weekly

D. Replacing auxiliary electrodes after each use

Answer: B. Regular calibration to ensure accuracy

Explanation: Earth testers need regular calibration to maintain accuracy, as measurement instruments can drift over time due to environmental factors and component aging.

7. What is the ideal earth resistance value for an electrical installation?

A. Less than 10 ohms

B. 50–100 ohms

C. 0.1–1 ohm

D. Above 100 ohms

Answer: A. Less than 10 ohms

Explanation: For safety, the earth resistance should ideally be under 10 ohms. Lower resistance values indicate better grounding, ensuring safe dissipation of fault currents.

8. Why is AC preferred over DC in Earth Testers?

A. DC is more expensive to generate.

B. AC minimizes polarization and electrolytic effects.

C. AC produces a higher voltage than DC.

D. DC readings are not reliable in conductive soil.

Answer: B. AC minimizes polarization and electrolytic effects.

Explanation: The use of AC avoids long-term chemical changes in the soil, ensuring consistent and reliable resistance readings.

9. Which factor can affect the accuracy of earth resistance measurements?

A. Soil moisture and temperature

B. Color of the earth electrode

C. Voltage rating of the tester

D. Length of the power cable used

Answer: A. Soil moisture and temperature

Explanation: Soil properties, such as moisture, temperature, and composition, directly affect earth resistance measurements. Wet soil has lower resistance, while dry and sandy soil exhibits higher resistance, influencing the test outcomes.

10. How often should earth resistance be measured in critical electrical installations?

A. Once every 5 years

B. Monthly

C. Annually or after major weather changes

D. Only after a fault occurs

Answer: C. Annually or after major weather changes

Explanation: Regular annual testing ensures that the grounding system remains effective. Additionally, severe weather events such as lightning or flooding can degrade grounding, requiring immediate re-measurement.

11. What happens if the earth resistance of an installation is too high?

A. Reduced system efficiency

B. Increased risk of electrical shock and fire

C. The system shuts down automatically

D. The tester will stop working

Answer: B. Increased risk of electrical shock and fire

Explanation: High earth resistance impedes the safe dissipation of fault currents, increasing the risk of hazardous voltage buildup on equipment, which can result in shock, fire, or damage.

12. What is the main difference between a traditional Earth Tester and a Clamp-On Earth Tester?

A. Clamp-on testers can measure insulation resistance

B. Traditional testers require an external power supply

C. Clamp-on testers do not require disconnection of the earth electrode

D. Traditional testers use wireless communication

Answer: C. Clamp-on testers do not require disconnection of the earth electrode

Explanation: Clamp-on earth testers measure resistance without breaking the circuit, making them ideal for operational installations where minimal disruption is desired.

13. Why is it important to use correct electrode placement during testing?

A. It ensures the tester operates within the voltage range

B. It avoids errors due to overlapping resistance areas

C. It reduces battery consumption of the tester

D. It prevents electrode corrosion

Answer: B. It avoids errors due to overlapping resistance areas

Explanation: Proper electrode spacing ensures that the test measures the resistance of the intended earth path only, without interference from surrounding soil layers or other grounding systems.

14. Which of the following factors can reduce earth resistance?

A. Using longer cables for electrodes

B. Adding salt and moisture around the earth electrode

C. Painting the electrode surface

D. Increasing the test voltage

Answer: B. Adding salt and moisture around the earth electrode

Explanation: Salt and water improve soil conductivity, reducing earth resistance. This practice is common in dry areas with naturally high resistance soils.

15. What should be done if an earth tester gives inconsistent readings?

A. Adjust the test voltage manually

B. Use only DC for future tests

C. Re-calibrate the tester and recheck electrode connections

D. Replace the auxiliary electrodes with new ones

Answer: C. Re-calibrate the tester and recheck electrode connections

Explanation: Inconsistent readings often result from improper calibration or loose electrode connections. Regular calibration ensures the instrument’s accuracy, while secure connections prevent erroneous measurements.